Step 2 Unscrew the 2 screws both A and B adjust the contact screw again and dont tighten the screws completely just adjust it slowly and patiently. The start voltage is 5V.

Top 10 Tattoo Machine Problems How To Troubleshoot Fix

Its frequency is 120-150 Hz.

. Coil Tattoo Machine Disadvantages. Coil tattoo machines are heavier than other types of tattoo machines. Dragonhawk Complete Coil tattoo kit Best Overall.

If and when you encounter this bend the solder lug out so that it no longer touches the frame. The result is that the. Types of coil tattoo machines There are the following types of coil tattoo guns.

Its height is 28mm and diameter is 0197. They also require more attention and care since they have many more moving parts than the rotary has. The mechanism works in the following way.

Thats the reason why they need more time to conclude finely detailed tattoos. Coil Tattoo Machine - Padiy Irons - Shader. High speed gives clear fine lines and color separation.

You can set the voltage to be 5-10V however 55-8V is the best. Prior to reconfiguring your machine you should identify spaces between the front spring and contact. Another type of tattoo machine is the rotary machine which is also very popular.

Coil cores are made of high-carbon steel. A direct electromagnetic current passes through the coils creating a magnetic field. If the device is working the noise and motion are humming.

Actions for Tuning Identify the Gap. Some people prefer the heaviness of the coil machine for nice crisp line work. 676 9000 FREE shipping.

Step 2 Unscrew the 2 screws both A and B adjust the contact screw again and dont tighten the screws completely just adjust it slowly. Coil tattoo machines are loud because of the principle of operation of electromagnets which creates a field that makes vibrations. While a rotary tattoo machine is still easier to use coil tattoo machines are more seasoned tested and traditional tattoo resources for the more experienced artists.

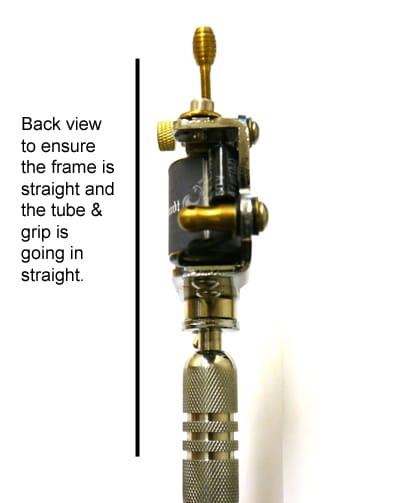

There may be a couple of problems. If you do not have a CUTBACK FRONT SPRING fitted then you should have the CONTACT SCREW touching the FRONT SPRING about 12 way down the length of the spring. The weight can become a problem when doing large tattoos over lengthy periods of time leading to short-term and possible long-term pain in your hand and wrist.

Ad by ElementTattooSupply Ad from shop ElementTattooSupply. However stainless steel is not a good option. If the needle is stuck in the back stem or in the tip or it is stuck by the dry color or the tip doesnt fit the needle which is harmful to the armature bar to move.

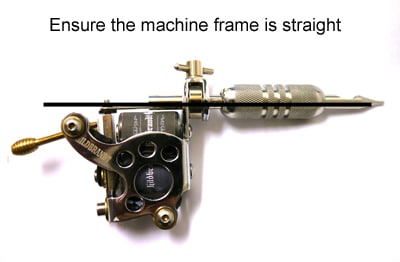

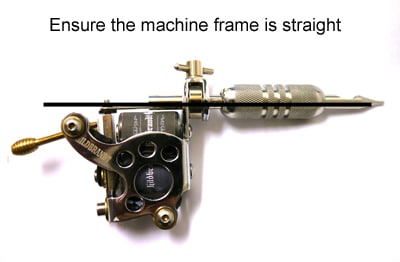

The distance between your point gap and air gap should be around the same. When you identify the gap between the front spring and contact screw you should loosen the. Theyre just typically made with two metal washers and a cylindrical core comprised of a highly-conductive material like steel or iron in between them.

You may need to sand the contact screw end that connects to the spring. Sometimes when using or maintaining your coil tattoo machine you may find a solder lug is bent over and touching the frame thus creating a new path for the electricity. If the armature bar can move normally like this when you press it then the armature bar is.

50V 47UF 7500 switchesmin. Two coiled wires are arranged in a square enclosure inside a coil tattoo machine. If a tattooist changes a toggle switch on the device the current passes through the machine.

It does have a. Step 1 please press the armature bar if the contact screw still touches the armature bar it means you didnt adjust the contact screw properly. Step 1 please press the armature bar if the contact screw still touches the armature bar it means you didnt adjust the contact screw properly.

As it is a liner machine the accuracy is unmatched. The spring pulls the armature bar up and contact. The coils are made of copper 12wrap for liner.

5 out of 5 stars. Soft iron is the ideal conductor but most forms of steel will work too. Ybeauty Tattoo Kit -2 liner coil machines using campus retro style.

The liners task is to inject the ink quickly so that it does not have time to flow out. This buzzing is caused by the electricity in the Coil Tattoo Machine. For the coil tattoo to work the machine needs to be connected to an outer power supply.

Adjusting the Contact Screw. When not in use the needle should stick out of the tips spout by about 1 mm maybe a little more but not less. Which is very suitable for traditional style work and is suitable for all handles on the market.

The magnetic field pushes the armature bar down which causes it to lose contact with the screw. Lets jump right into the discussion and the coil tattoo machines reviews. It really is a testimony to how many places use the Coil Machine over the Rotary that you practically see it in every tattoo parlor portrayed in the media to the point that its burned in your brain that there should be a buzzing when you get a tattoo.

After-Sales Guarantee-If you are not satisfied with the product or the product is not suitable for you if the tattoo machine you receive has quality problems or any. Press down on ARMATURE BAR until it touches the COIL CORE and adjust the CONTACT SCREW so there is. Armature bar still touches spring the tattoo machine cannot work properly.

Either the capacitor fried or the connection of the capacitor and the coil are not correctly connected. The coil machine can be quite heavy due to the weight of the magnets the coil and the armature bar. Try and adjust the contact screw.

If thats doesnt do anything it maybe the problem with the coil. Moreover this is also an easy-to-handle coil tattoo machine owing to the lightness of the profile. Cons to the coil tattoo machine happen to be that it requires a good bit of experience before you start to work with them which makes the entry-level hard for many.

The two machines differ both physically and in functionality. How far should the needle in the tattoo machine stick out. The sterling silver contact screw makes the whole machine more conductive.

Check your air gap distance between top of coil and bottom of spring If the air gap is to large lower volts wont be enough to draw the abar to the coil. Lastly this is one of the few coil tattoo machines that can work for almost 8 hours at a stretch sans heating up. A tattoo machine coil has these same basic geometrical components.

How To Fix Tattoo Machine Problems Tattoo Kits Tattoo Machines Tattoo Supplies丨wormhole Tattoo Supply

What If Tattoo Machine Not Working Wormhole Tattoo 丨 Tattoo Kits Tattoo Guns Tattoo Inks

Top 10 Tattoo Machine Problems How To Troubleshoot Fix

Top 10 Tattoo Machine Problems How To Troubleshoot Fix

What If Tattoo Machine Not Working Wormhole Tattoo 丨 Tattoo Kits Tattoo Guns Tattoo Inks

What If Tattoo Machine Not Working Wormhole Tattoo 丨 Tattoo Kits Tattoo Guns Tattoo Inks

How To Tune Coil Tattoo Machine Cnc Tattoo Supply

What If Tattoo Machine Not Working Wormhole Tattoo 丨 Tattoo Kits Tattoo Guns Tattoo Inks

0 komentar

Posting Komentar